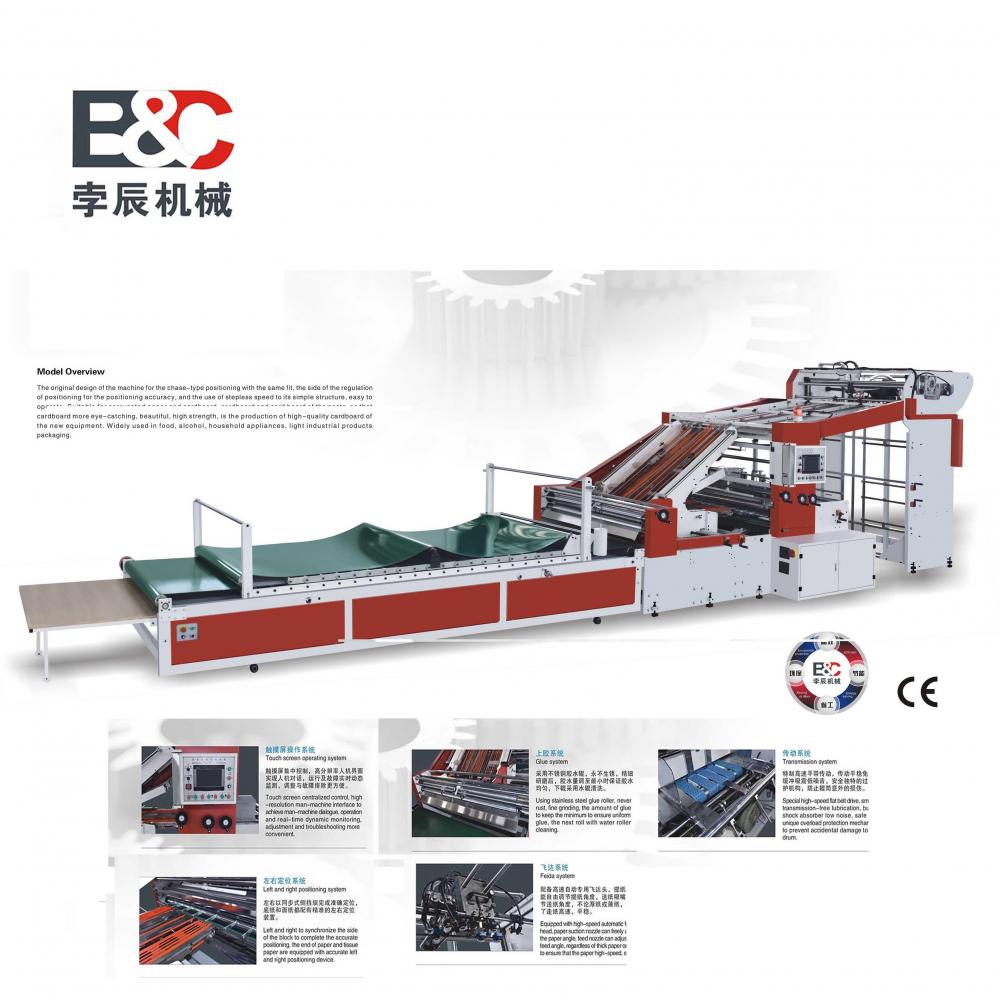

Product Description

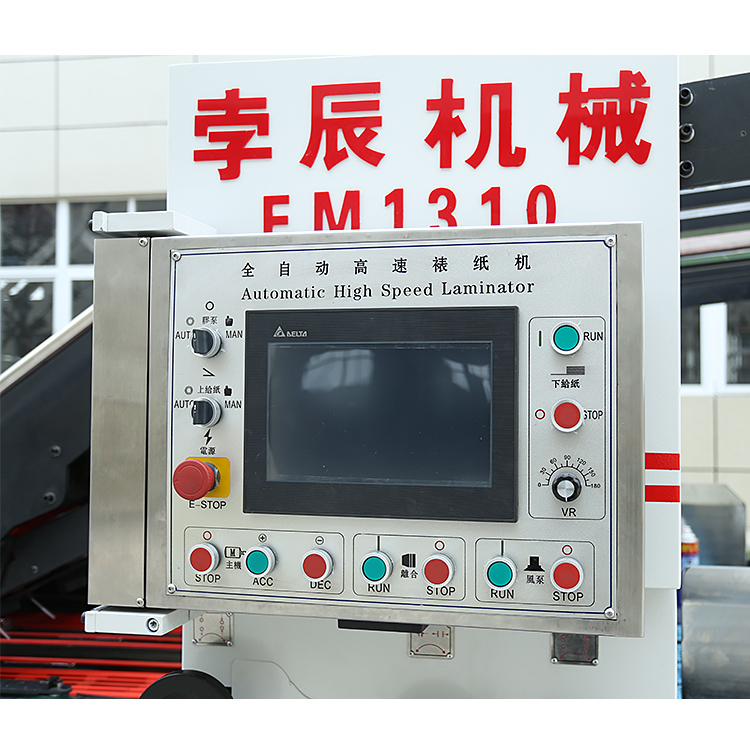

Automatic high speed flute laminating machine

1.1 Overview

1.1 Overview

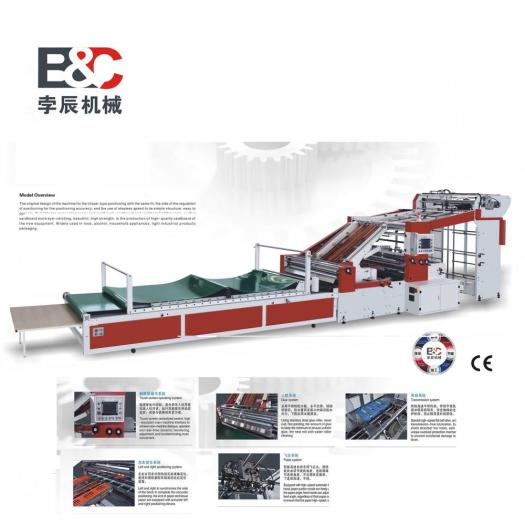

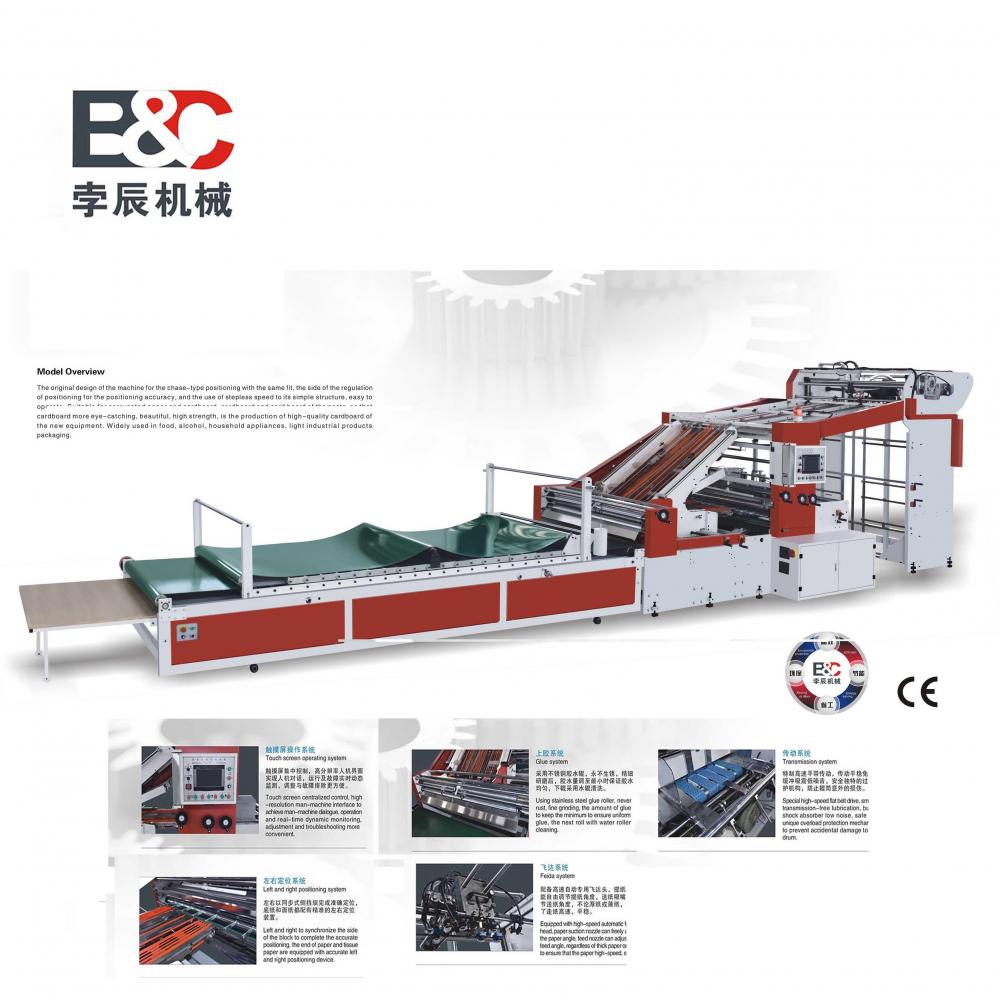

This machine is designed for

pre-compliance with regulations chase block positioner fit, side road in

regulation for fixed positioning control precision fit, and the use of variable

speed so that its structure is simple, easy to operate. Suitable for corrugated

paper and cardboard, the cardboard and cardboard, make cardboard more striking,

beautiful, high-intensity, high-quality paperboard production of new equipment.

Widely used in food, wine, home appliances, light industrial products

packaging.

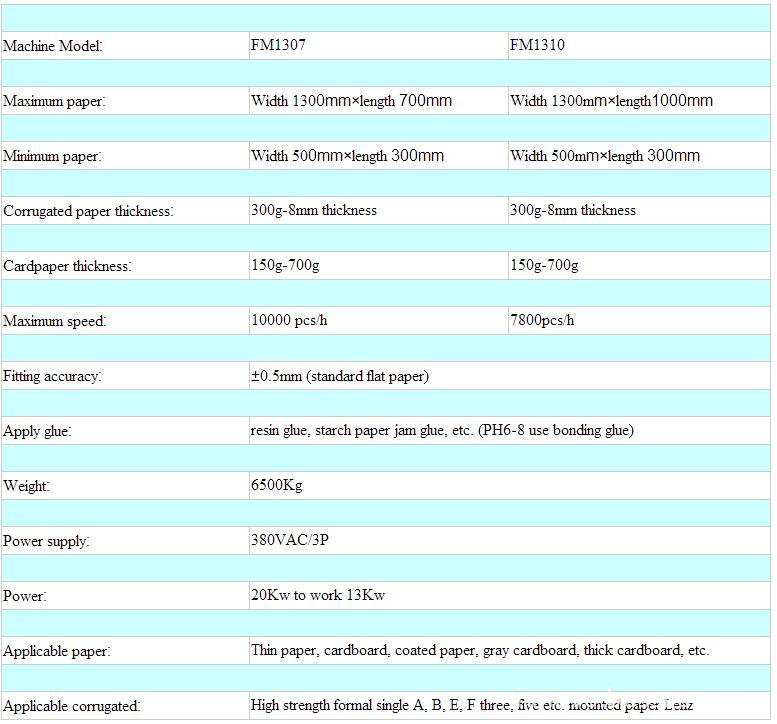

1.2. The main

technical parameters

1.3 Series Product

Description:

1. This machine stations and body

are all made by large processing center and complete in one time to ensure the

accuracy of each station and equipment operation more stable.

2. Cardboard feed mechanism: Configuring

high speed dedicated feeder head, regardless of thick or thin paper it can ensure

the paper feed speed and smooth.

3. Cardboard lifts: In line with the

high-speed feeder, equipped high strength worm reducer, to ensure the instant

speed stability.

4. Cardboard loader: The E-type double-notch

unique design, the production of paper can be pushed directly into the hand

truck, shorten the stacking paper time and improve efficiency.

5. The end of the paper system: servo motor

control system, high sensitivity, high speed, to ensure the smooth end of paper

out of paper, no paper jams and other characteristics.

6. The end of paper adsorption system:

Frequency jams and agility with the solenoid switch, to ensure that the end of

paper completely adsorbed, and the operation is simple.

7. Glue wheel: thick plated steel wheels,

fine grinding surface, adjustable amount of glue to 8g / sq.m., ensure a

uniform thickness of paper glue.

8. Glue supplement: The liquid level

control, to ensure that the glue is automatically added, to ensure continuous

production.

9. Paper Separation: For high-speed operation,

using the separation claw, making glued paper detach from the glue wheel

effectively.

10. Fit Positioning: Positioning prepositive

mode, left and right sides both have side block rules, ensuring high-speed

precision fit.

11. Transmission: imported from Germany,

chain and belt drive, ensure the drive precise, stable and low noise.

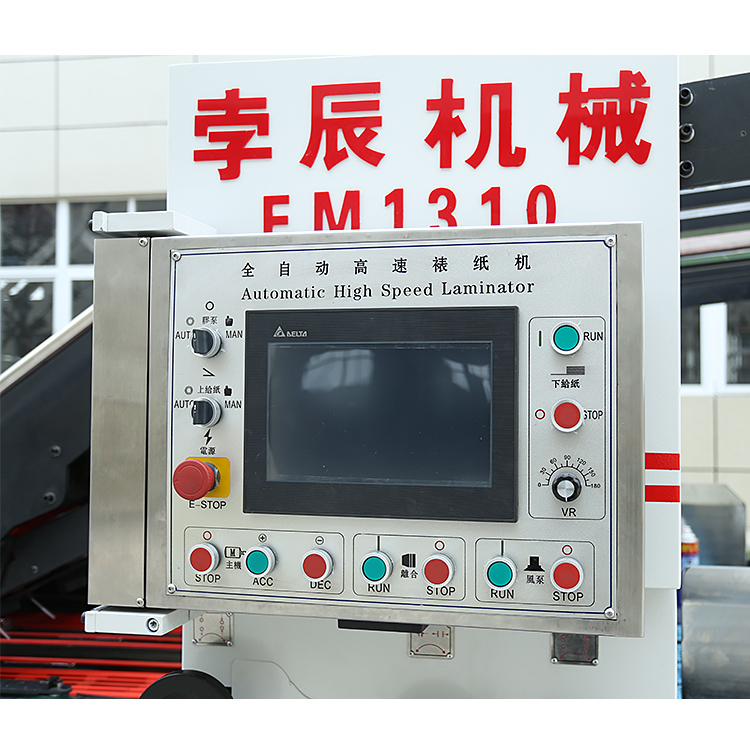

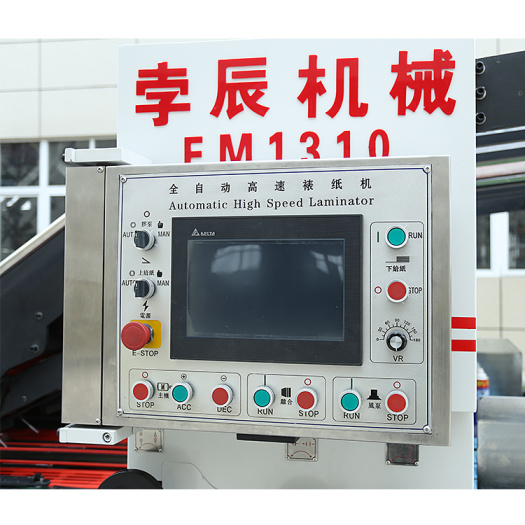

12. Operating system: Use HMI touch screen as

operations center, connected to PLC, so it can warn the information to detect

failure, abnormal condition and operating speed displayed on the screen, at a

glance, and the ability to detect maintenance, work records, online Live View

in time, truly reflect efficiency.

13. Electrical system: well-known brands,

designed in accordance with the European CE standard, careful manufacture,

ensure the machine stability, high efficiency, low failure.

1.4 More Photo

1.Back Photo

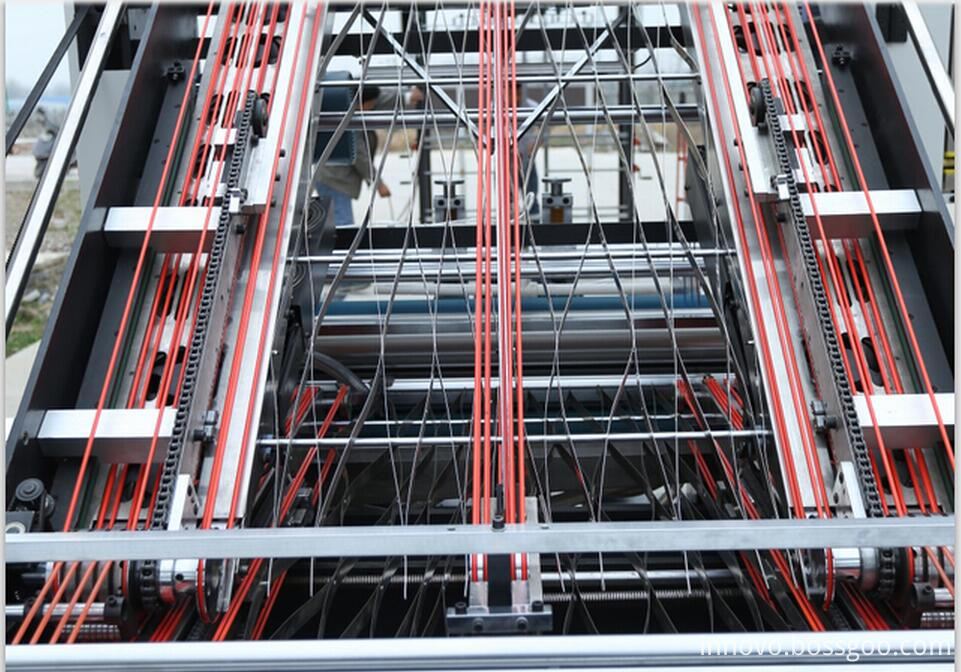

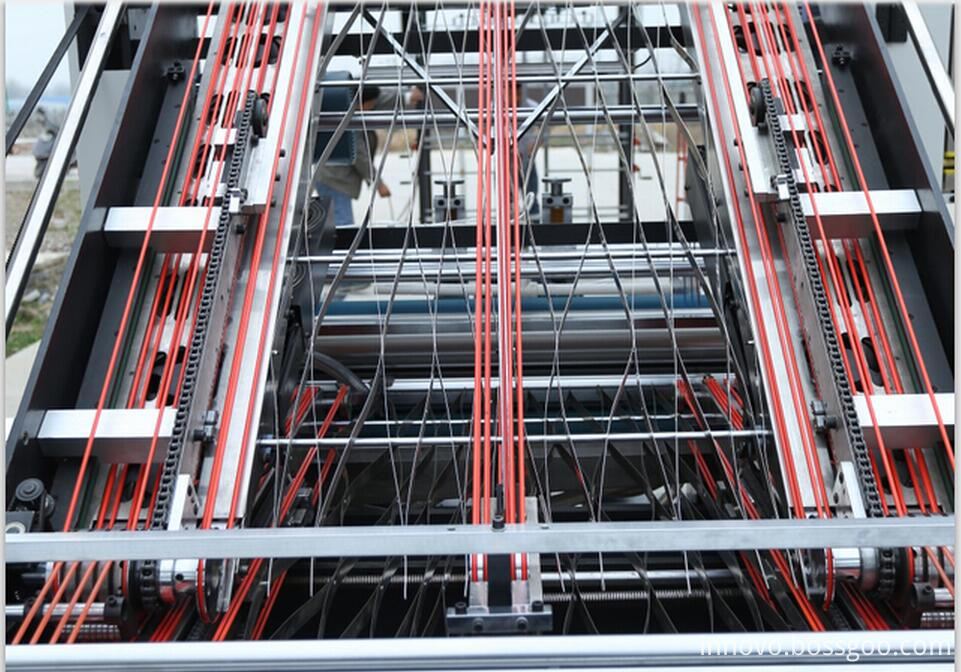

2.Belt Photo

.png) Contact Now

Contact Now

1.1 Overview

1.1 Overview