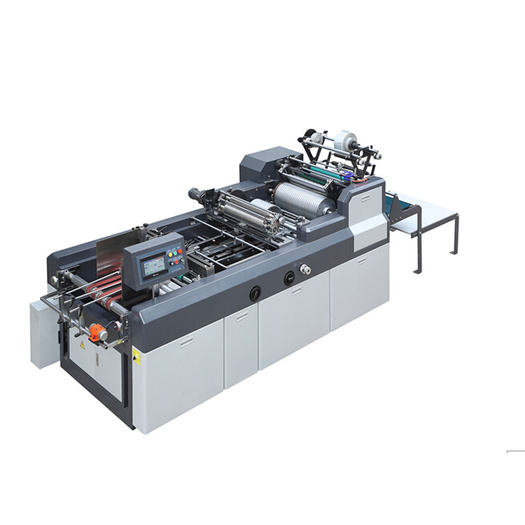

Product Description

Introduction of Product :

700 Series Window Patching Machines are widely used for sticking films on the windows of various color window boxes ,color boxes and paper boxes,e.g medicine box ,shirt box,etc. It is developed on the original window patching machine in light of customers` requirements. Our research and development team, through the continuous improved &perfect human design,let the machines be easier to operate and better in efficiency, accuracy and stability.

Both basic components and major automated accessories employ the proprietary technology of this company. Therefore,700 series Window Patching Machine can meet customers` requirements at a higher level.

ZKT-700 is the Innovation Machine of Window Patching Machine, Manufactured & Designed by our own Technical Team.

Structure Characteristics :

ZKT Series window patching machine could Gluing and Pasting film on the after die cutting paper cartons` windows.Flat belt paper suction mechanism ,single paper feeding without shutting down the machine ,Brass pin position checking ,accurate locating.when paper arriving the Gluing part. Automatic gluing by rubber roller, location, and then spread to the feeding film part, film attached by gas suction drum and then let the film to the correct position of paper window, film will be released and rolled, then complete the paste process

ZKT series Window Patching Machine are well designed with micro device and easily adjustment , It is an ideal equipment of paper lamination processing.

ADVANTAGE:

1.The paper feeder is controlled by PLC with a human-computer interface. The length of paper to be fed can be entered on the touch screen, so that paper can be input quickly and accurately.Also,it applies to card paper and corrugated paper.

2.Film Feeding Part is controlled by the Imported Servo System, input the needed Film`s Length on the Touch Screen, Saving the adjust time and highly precision.

3.The Gluing Part install a small Motor, can rotate by itself. It also can be be easily drawn out for setting up and cleaning.

4.The Film Cutting Part & the Film Patching Part install free axial rotation,is used for various shape & position of paper window, Saving the adjust time , Greatly improve the production efficiency.

5.Based on the original mechanism, the layout of each section of this product has been improved in order to reduce the adjusting time, so that it becomes more efficiency and friendly.

Technical parameters:

|

Paper GSM

|

250 - 1000g carton paper and Flute / corrugated paper

|

|

speed

|

4000-10000pcs/h

|

|

Paper Length

|

120 - 700mm

|

|

Paper Width

|

200- 690mm speed

|

|

Film Width

|

30 - 400mm

|

|

Film Thickness

|

0.03 - 0.15mm

|

|

Power of Pump

|

1.5 kw

|

|

Main Power

|

2.2 kw

|

|

Weight

|

1800 kg

|

|

External Dimension

|

4200*1400*1500 mm

|

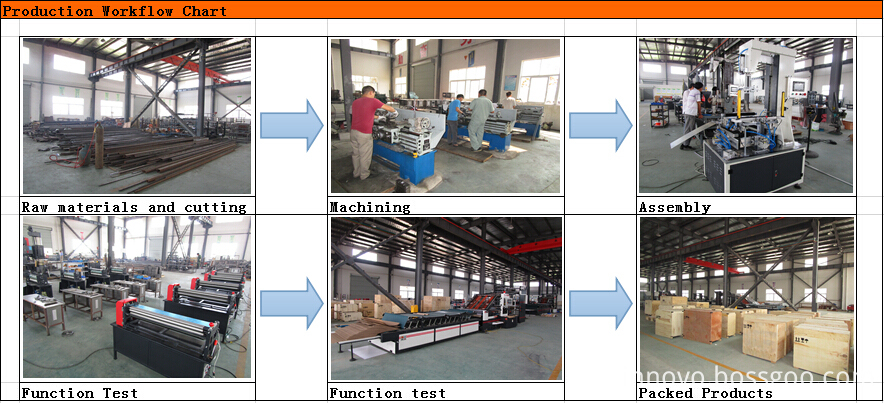

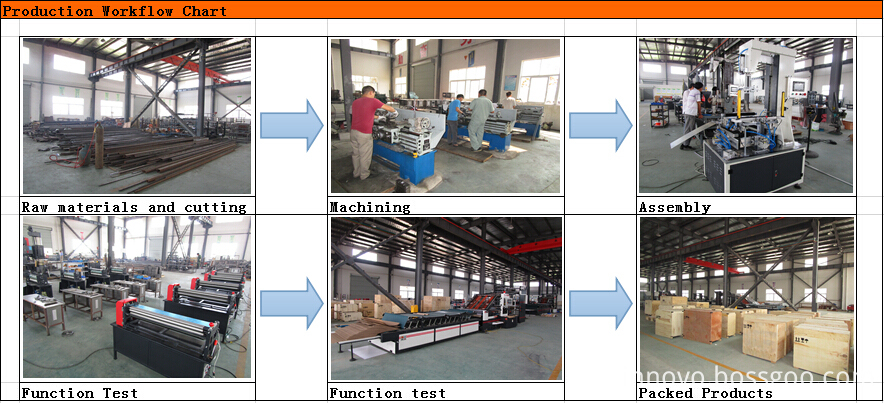

Packing

1. The packing is confirm to export wooden case standard, strong and durable. The wooden case`s thickness is generally 1 cm.

2. In order to be waterproof, we usually use bubble film to wrap machine.

3. We can handle shipping for customers too.

Service

We provide 12 months warranty. During warranty, we provide free technical support and free normal spare parts for replacing, except for man-made damage.We can go to your country to debug machine when you have questions can not resolve,but you must pay 100usd/day to our engineer.

Innovo look forward to long term cooperation with customers, we will make best service and aftersales service for all of our customers.

Company introduction

*With 10 years' Experience

*Having ISO 9001-Certified Factory

*Strong R&D capability

*High Quality Guaranteed

*First Class Service And Best Prices

*Primary products:

Automatic High Speed Flute Laminater

ZXSCM Book Case Making Machine

650UV Coating Machine

ZX-650C Manual Paper Pasting Machine

Box Making Machine

Hot Melt Gluing Machine and Gluing Machine

Table Gluing Machine

Paper Pressing Machine.etc

Welcome to visit our factory!

.png) Contact Now

Contact Now