Product Description

fully automatic book sewing machine

Description:

1.ZXSX-160 fully automatic sewing machine, there are two different models, 43-and 51-type,43type max size of 320mmx430mm,and 51type, compared with 320mmx510mm.ZSX-160/51type sewing machine performance, can be a variety of different sizes of signatures for sewing process.(Such as double this,large format pictures)

2.Mitsubishi HMI using the latest PLC,configure a Taiwan Willen 10inchtouchscreen that canrotate 360degrees for easy operation personnel can operate in any orientation.

Programs can rotate 360degress for easy operation personnel can operate in any orientation.

Programs can store up to 20 different types of sewing program,and can be called repeatedly.

Shows,the production output,running speed,equipment and alarm messages.

3.There are different types of production by the signatures,the program has automatic transmission feature.Automatic adjustment of production speed (eg,a book with a thin thread or post sets page,the machine will automatically height and hit quote wheel down speeding,Signatures has finished a location automatically accelerate to normal speed thereby improve overall production efficiency,reduce downtime)

4.automatic adjustment for functional (simply enter the book size, the number of stickers and other parameters. Machine will automatically adjust to the appropriate location)

5.All pneumatic handling systems are machine Japan CKD brands.CKD Corporation:the world`s largest manufacturer of pneumatic components.

6.ZXSX-160,160/51 graphic novel detection system can be installed,the machine uses the latest intelligent analog video technology.

7.Conveyor will send the signatures over exposing page ,up and down the four vacuum nozzle,to meet the different requirement of exposing page.In case of a ring lining posts or posts.Specially designed hair allowed signatures with suction after a produce an air cushion signatures,thus effectively eliminating the phenomenon of suction double sheets.

8.Suction device and robots will bottom most signatures and signatures separation,followed by separation of the teeth hundred signatures extracted form the hopper.this performance combined with lower signatures heap,continued feeding signatures tilt helps eliminate the phenomenon Of surface scratches.

9.Taiwan automatic central lubrication system,the use of quantitative reducing valve,equipment maintenance becomes very simple,the system can be set at an appropriate time on the sewing machine oil lubrication points automatically lubricated.No oil pipeline rupture,hydraulic reach the set,the machine will automatically alarm shutdown,trouble shooting before normal production.

10.Sewing needle and looper very short straight,which ensures its easier to insert the threaded hole on the spine needle play.Thus achieving high quality sewing effect,eliminating needle looper phenomenon.

11.Electrical parts used Mitsubishi PLC and Taiwan Willen latest touch screen, remote Internet monitoring service,free from worry.

12.All imports of electrical switches,ensure that equipment runs more stable,more secure,long life.(Japan Mitsubishi PLC,Taiwan Willen touch screen,Schneider electrical switches,etc.)

13.If the signatures are not used when the length of edge folding suction signatures can also be separated.In order to meet mortgage page uses,requires a minimum side length of more than 8mm.

14.Lock thread needle seat is independent for each component can be replaced individually.If worn without the need to replace the entire lock thread,saving maintenance costs.

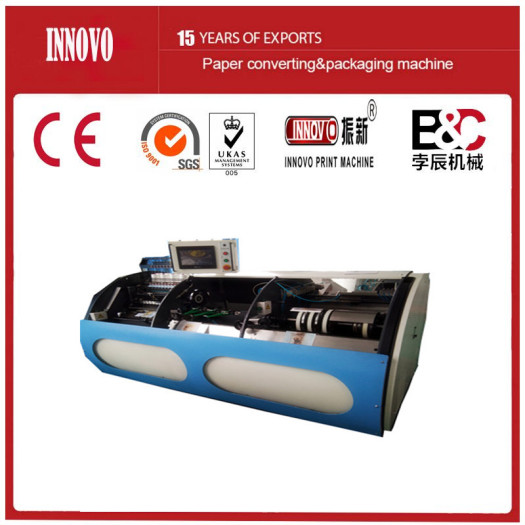

15.Front cover,the shutdown automatically when opened,allows the operator to life downtime caused by faults.Start the machine automatically turns Off when the safety cover,reduce labor intensity of operators.Safer and more efficient.Two large oval transparent window is also convenient for the functioning of the device were observed.

16.You can click on the control panel to enter the equipment maintenance interface for electronic and pneumatic components can be checked directly displayed IO interface diagrams and location of electrical switches, circuit diagrams can without overhaul.

17.Suction device imported vacuum generator,compared with the traditional air pump to reduce noise,eliminating the heats generated by the wind pump itself,long-term use of maintenance-free advantages.

18.Power section complete with imported Italian aluminum motor to achieve high efficiency low energy consumption.Compared with other models,can save energy more than two thirds,the whole power only 2Kw,real energy efficient equipment.

19.The core components of the machine.All of Germany Sa Site steel production by the Taiwan head quarter processing(such as cams,locking thread,etc.)to ensure that equipment precision long wear.

.png) Contact Now

Contact Now