Product Description

1, Corrugating Machine

Roll Diameter: 266mm

The roller, pressure roller, glue roller moving can pneumatic adjust

feeding paper by Vacuum. Here is the device of air volume adjustment, make sure the corrugated stability shape

corrugated roller, pressure roller bearings with high temperature grease lubrication.

gluing device used by automatic cycle system

The upper and lower corrugating roll with 48CrMo high-quality chrome molybdenum alloy steel, heat-treated, hardness HRC56-60 surface by grinding.

The surface of coating roller embossing and chrome plating.

2 Bridge Transport aircraft with a bridge.

Suction device attached to the bridge: and can be adjusted.

Both sides here are safety railings and staircases.

3, preheater: Preheat roller diameter: 400

Preheat roller heat-treated, high hardness, wear resistance of chrome-plated surface treated well, enhancing thermal conductivity effect.

4, the glue machine High-precision a lox roller coating slurry, slurry coating evenly pulp consumption is small.

Pressure plate with pressure roll paper unit

Auto-cycle for the glue to prevent glue precipitation, with a preheating device, can accelerate the glue paste, improve bonding strength.

5, machine-free shaft paper planes Base Diameter: Φ1300mm

Machinery without the lift shaft of paper roll holder, clamping, release, move, electrical controls are right in the previous paper fast rotation flexibility, tension control with manual brake, top with tapered top.

6, drying shaping system Hot-plate surface by the grinding treatment.

Hot-plate pressure roller for intensive, the overall control of lifting power.

Department of cooling and sizing an intensive floating roller design.

Wear resistant rubber drives roller outsourcing to improve cotton belt life.

7, mechanical Cut Machine Cutting range: 500-2400mm

Cutting precision: ± 2.5mm (uniform pm)

P-transmission manually adjust the speed to change the required length of the cardboard.

Knife roller gear with a gap between the adjustment device and gear parallel devices, in order to ensure operation

Smooth, higher precision.

Main drive power source is input, synchronous effective, cutting and high precision

Technique parameter

|

Max. paper width

|

1600mm

|

|

Type of flute

|

UV/A ,B ,C ,E

|

|

speed

|

50m/min

|

|

Adhesive material

|

Corn or Potato diastase

|

|

Heating way

|

heat conducting oil steam electric heating

|

|

power

|

Three phases, four lines 380V 50Hz

|

Facilities

1Vacuum absorption corrugated machine 1set

2bridge 1 set

3preheater 3set

4gluing machine 1set

5no-axis paper holder 2set

6dring&sizingsysyterm 1set

7cross-cutting machine 1set

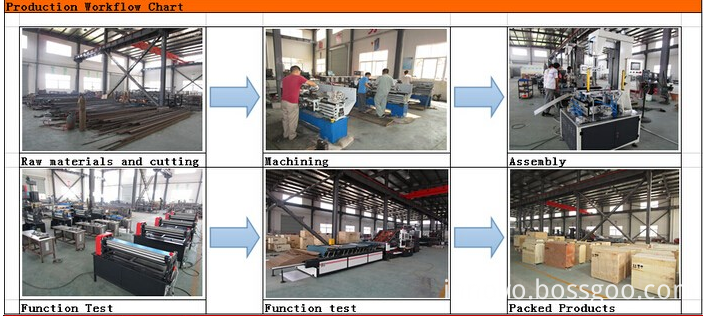

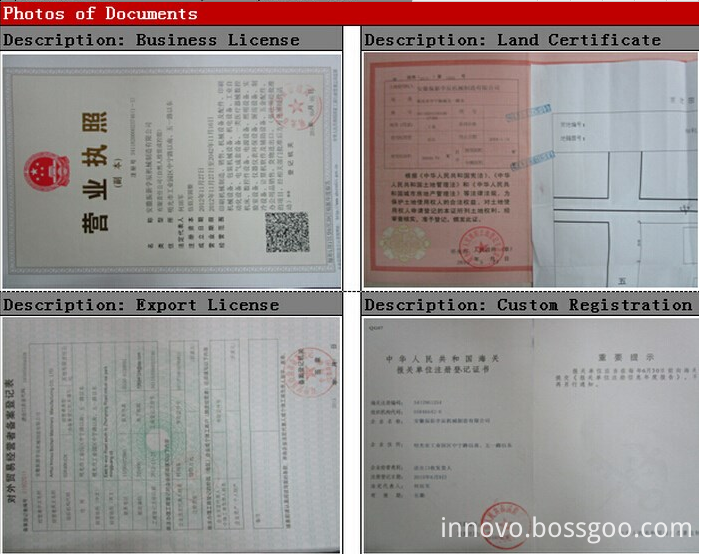

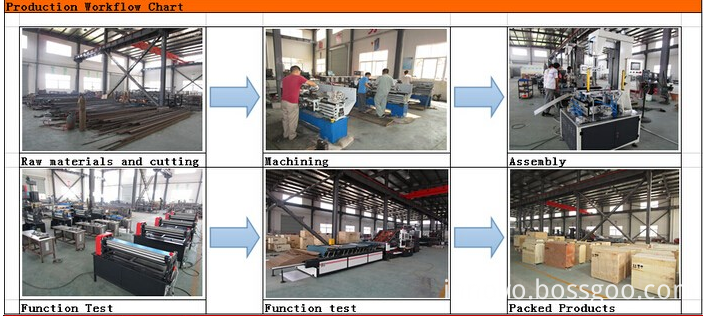

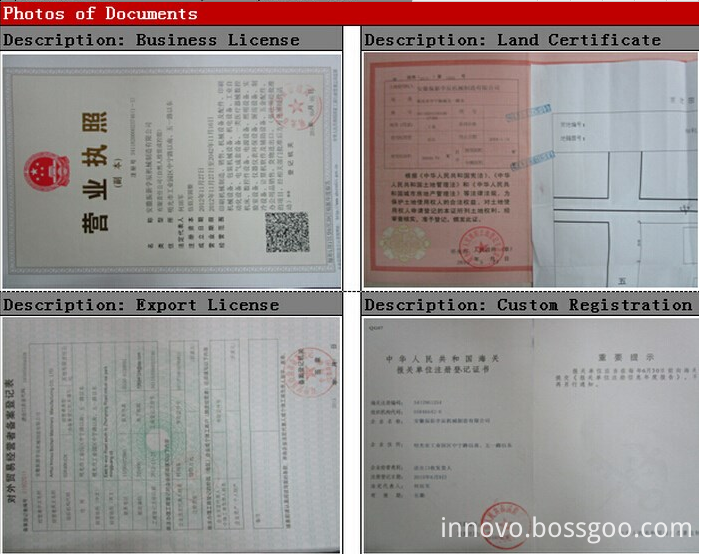

More photoes of factory and company documents

.png) Contact Now

Contact Now