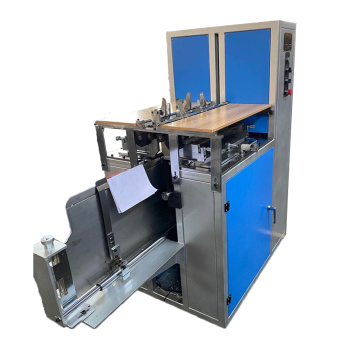

Bookbinding auxiliary machinery is other than the binding machine bookbinding related machinery, it contains punching machine, folding machine, with page machine, book sewing machine, coil binding machine, pressing machine, three sides book cutting machine and so on

The processing technology of the hardcover book:

1 flat:Applanation is on a dedicated machine press books, so that the book block is strong, soothe, to improve the quality of bookbinding books.

2 brush glue:By hand or mechanical brush glue, so that the book block basic training,the next step of processing, the book does not occur with each other.

The 3 cutting:The book block, the dry brush gum base for cutting, into light book core.

4 grilled circle:Human or machine, back into the spine part, a circular arc, called grilled circle. Rounding, the whole book book can stagger, easy to read, the book block of bridge is.

5 ridge:Human or machine, put the book core splint clamping added, in the book block both positive and negative, close to the spine and lining connectionedges, extrude a dent, the spine slightly outward bulging process, called the ridge, thus preventing the book block rounding back after the circulardeformation.

6 processing of spine:The processing includes: Brush glue, adhesive paste, paste, a bookmark with gauze plug cloth spine, paste paper.

Connection strength of plaster gauze can increase the strength of the links in the book and the book block and type.

Plug for cloth, paste on the book core back the head and tail ends, soclosely linked the book, not only increased the firmness of binding books,and the books become beautiful.

The paper must be put in the middle of the spine book block back, notwrinkle, foaming.

The type of case - making

Making is a hardcover book cover. Case making materials have strengthand wear resistance, and has a decorative effect.

A piece of fabric, the cover, back cover and back together made of case - making, called the whole case. The front cover, back cover with the same fabric, but the back with another piece of fabric made of case - making, called the blending.

As a case, first by the specified dimensions cutting cover material andbrush glue, and then the front seal, after sealing cardboard compaction,location (called swing shell), wrap the edges and four corners, makingflattening is complete type. Because of low efficiency of manual operation, is converted to mechanical system type.

Prepared case making before and after sealing, and on the back of the book, imprint title and patterns. In order to adapt to the back of the arc shape, after finishing the end of case, the need for rounding.

Contact Now

Contact Now